Technology overview

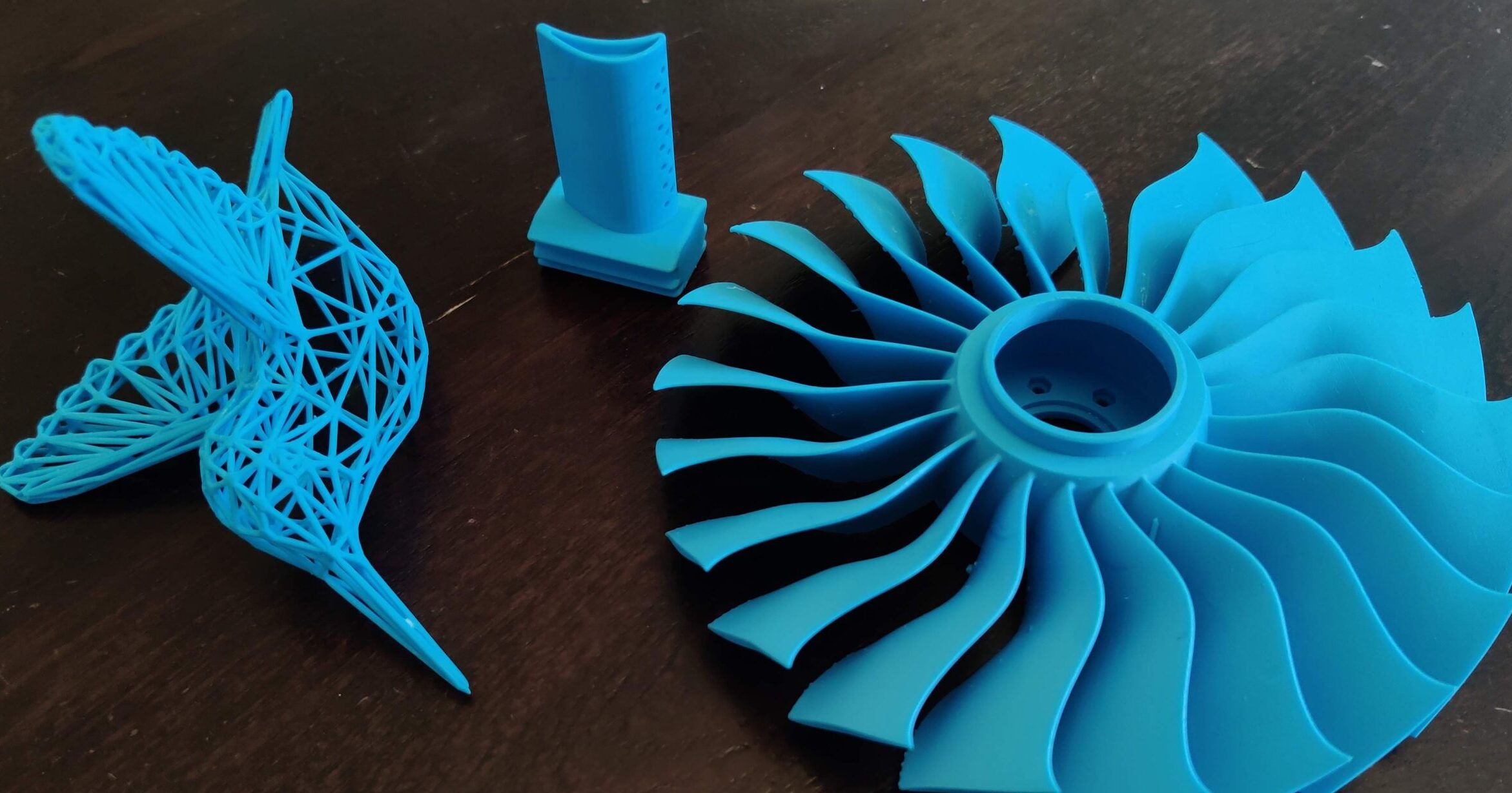

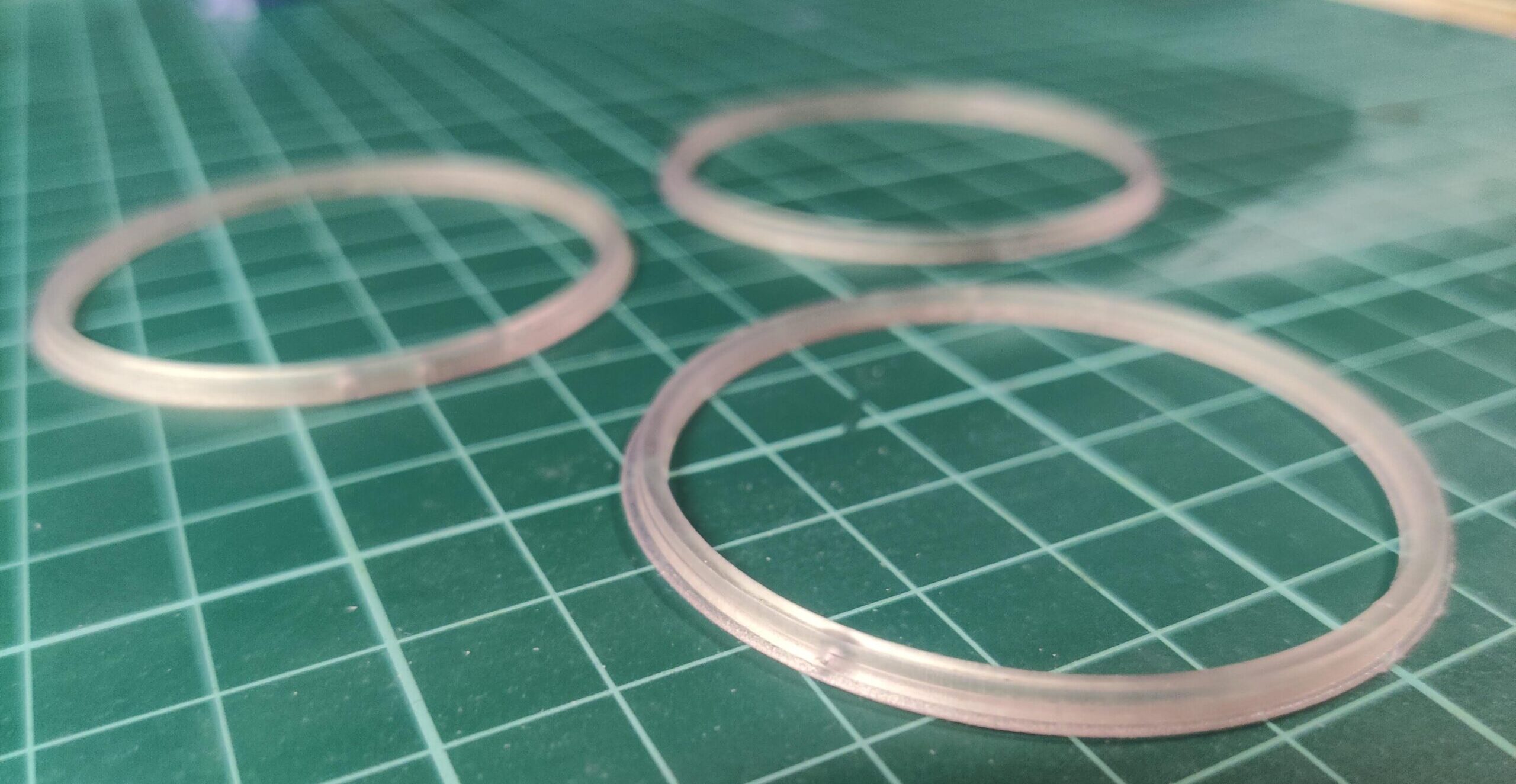

SLA is an additive manufacturing technology that employs photosensitive resins cured by UV light to craft intricate 3D objects. Ideal for prototyping and small-scale production, SLA offers unmatched detail, making it perfect for complex geometries. Its dependable performance across industries ensures durable end-use parts and functional prototypes, reflecting a commitment to precision and versatility in modern manufacturing.

Max part dimension

350 x 250 x 250 mm

tolerance

± 0.5% (min: ± 0.1 mm)

lead time

From 1 Calendar Day – (We work 7 days a week)

resolution

From 10 microns

SLA uses:

High-Resolution Prototyping

SLA is known for its exceptional detail and high resolution, making it an excellent choice for creating prototypes with intricate features and fine surface finishes. This technology is often used to produce highly accurate visual prototypes that closely resemble the final product, aiding in design validation and communication.

Key Benefits:

Medical, Dental and Jewellery Applications

SLA is widely used in the dental and medical fields for creating precise dental models, surgical guides, orthopedic implants, and anatomical models. Ideal for applications where precision and accuracy are critical, helping improve patient outcomes.

SLA’s ability to produce detailed and intricate designs has made it a favorite in the jewelry and artistic industries. Jewelers and artists can create intricate, customized pieces with fine details, textures, and smooth surfaces that are hard to achieve with traditional manufacturing methods.

Key Benefits:

Complex Geometry’s

Excels in fast, high-volume manufacturing, making it the go-to choice for producing thousands of functional parts. Its cost-effectiveness and efficiency allow for streamlined batch production, while maintaining high accuracy and consistency. Ensures rapid and reliable production of large quantities, meeting the demands of diverse industries

Key Benefits: