Technology overview

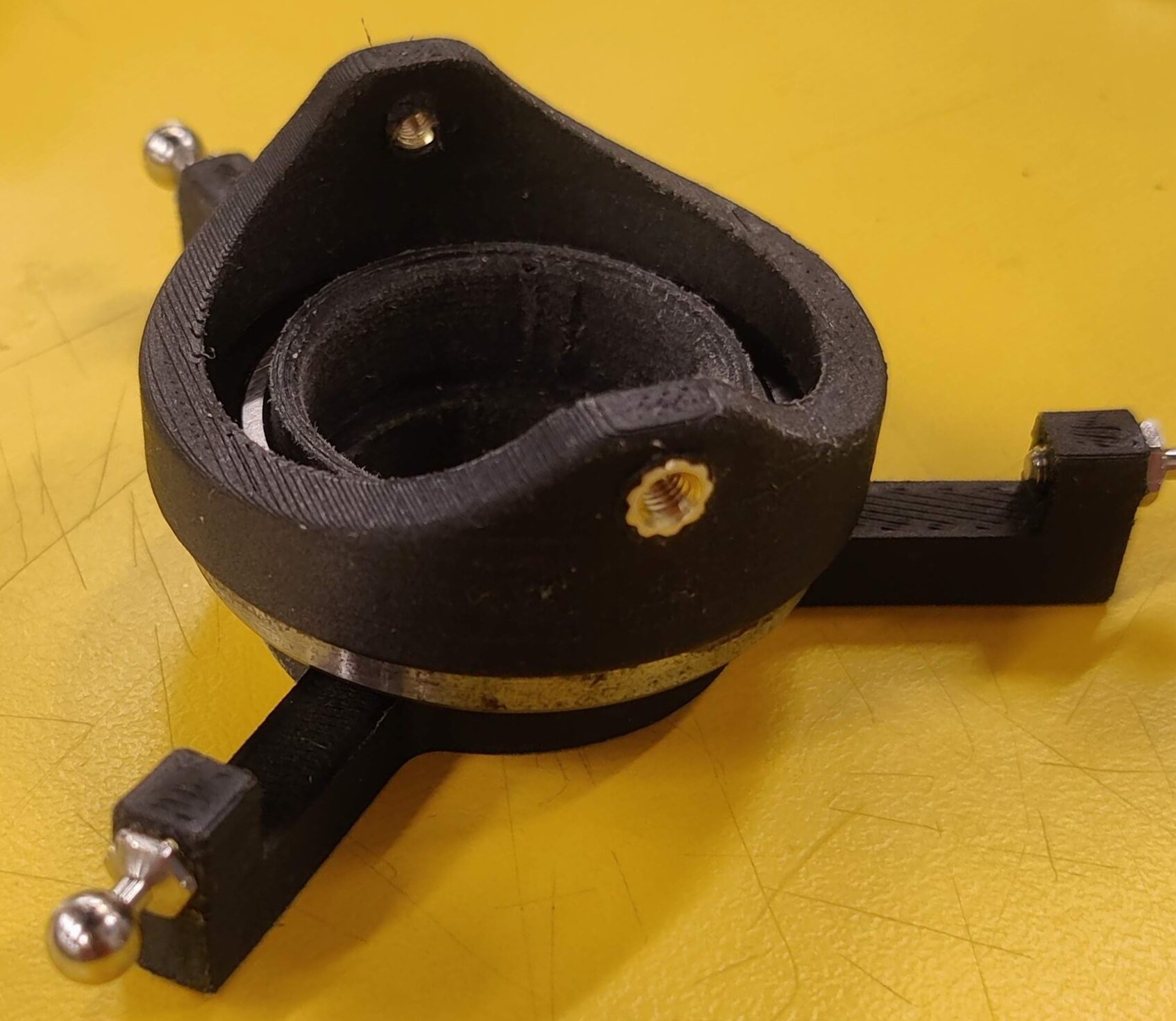

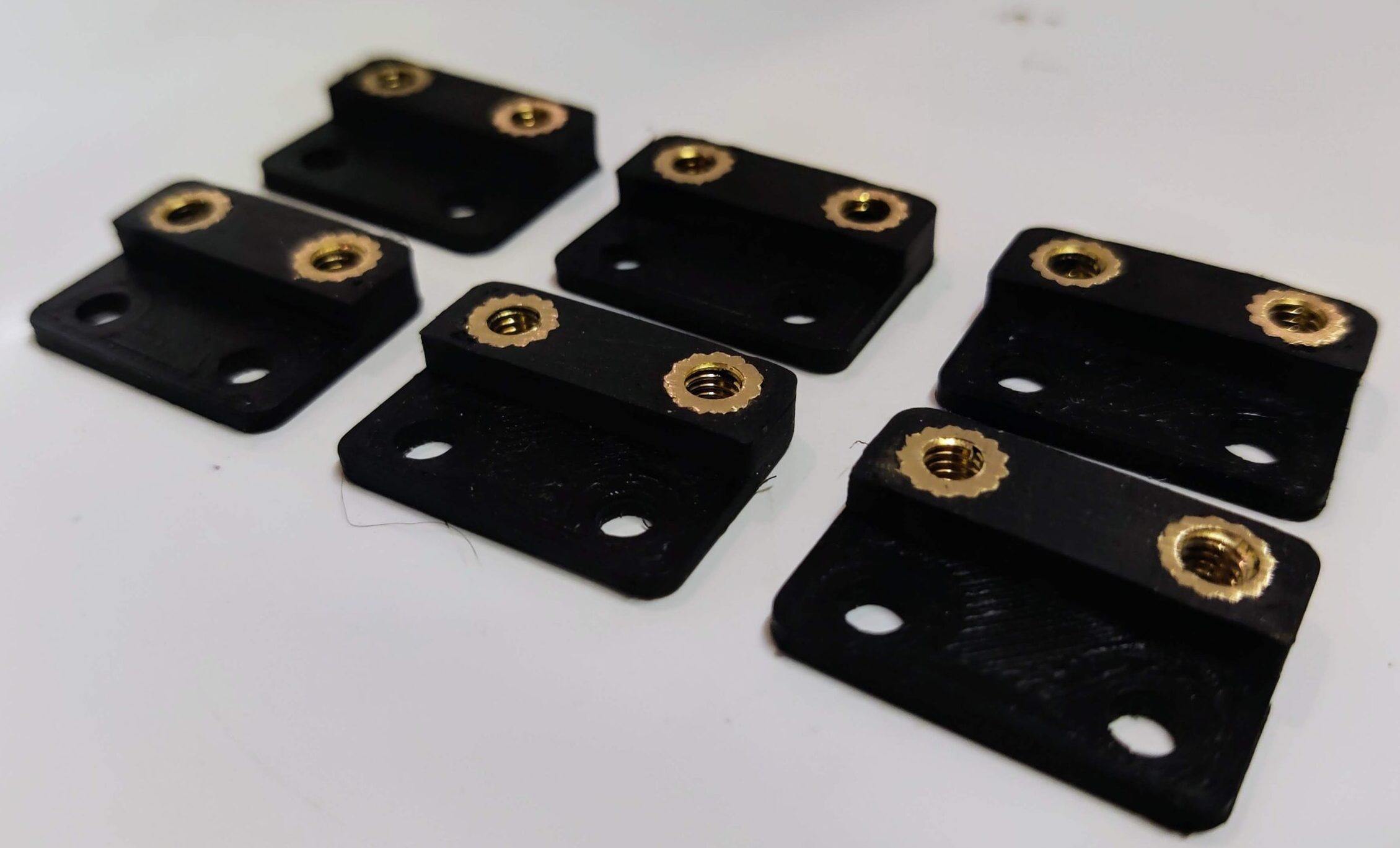

Threaded inserts are essential components in 3D printing, enabling the creation of secure, reliable connections within printed objects. These inserts provide threaded receptacles that enhance the versatility and utility of 3D printed parts.

Threaded inserts are used to create threaded holes within 3D printed parts, allowing screws, bolts, or other fasteners to be securely attached.

Max part dimension

n/a

tolerance

n/a

lead time

From 1 Calendar Day – (We work 7 days a week)

resolution

n/a

Benefits

- Enhanced Strength: Threaded inserts reinforce connections, making them more durable and resistant to wear and tear.

- Versatility: Threaded inserts allow for the easy assembly and disassembly of parts, facilitating repairs and maintenance.

- Material Compatibility: They enable the use of different materials for the threaded portion and the main 3D printed component.

Benefits

- Enhanced Strength: Threaded inserts reinforce connections, making them more durable and resistant to wear and tear.

- Versatility: Threaded inserts allow for the easy assembly and disassembly of parts, facilitating repairs and maintenance.

- Material Compatibility: They enable the use of different materials for the threaded portion and the main 3D printed component.

Types

Common threaded inserts include heat-set brass inserts, press-fit threaded inserts, and ultrasonic inserts. The choice depends on the material, design, and application.

lead time

From 1 Calendar Day – (We work 7 days a week)